It’s no secret that automation is a hot topic right now in virtually every industry. The ability to use software to save employee hours and costs and defer that burden to a machine that can process tasks in a fraction of a second is essential for any business with low-profit margins, like the restaurant industry.

After all, every task is critical, and every second counts when your employees are on the clock. And when it comes to finance processes like invoice reconciliation, EDI and automation are rapidly changing the way companies approach these tasks.

This article will explore EDI and invoice reconciliation, and how adding EDI can benefit your business over the long run.

How Automated Invoice Reconciliation Can Benefit Your Company

Any process that a human can do, a machine can do faster and more efficiently, even tasks vital to a business’s profitability, like invoice reconciliation. It is essential to reconcile your invoices as accurately as possible. Doing so will reap the following benefits for your company:

- Saving work hours. Pre-automation, businesses will assign multiple employees to sift through invoices for hours at a time. With automation, these same employees can be contributing to other tasks, while EDI software reconciles the invoices for them.

- Reduce invoice errors. People make errors all the time, even best our best intentions. Invoice errors can profoundly negatively impact a business, from overpaying/underpaying a supplier to not billing a client correctly. The software will not make these same mistakes as all values are based on computer calculations and checks and balances are in place.

- Reconcile many invoices simultaneously. Humans can only process one invoice at a time. The software can process invoices in a fraction of a second. By reconciling many invoices quickly, you will save valuable employee hours.

- Prioritize other more critical business processes. By automating invoice reconciliation, you can re-assign your human employees to other tasks. Every task needs to be prioritized for maximum efficiency to ensure maximum profits.

- Establishes precedence for more automation. Automation saves money, especially when a whole business process can be automated, as in the case of EDI.

- Cloud-stored data. Even the best office practices of data storage are no match for cloud-based storage. Cloud data can be accessed at any time, in any location, as long as you have online or offline access to your data. The same cannot be stated for data locked in an office. By utilizing cloud storage, EDI allows you to save copies of reconciled invoices, and check the reconciliation process for errors when you need to.

The Value of EDI and Invoice Reconciliation

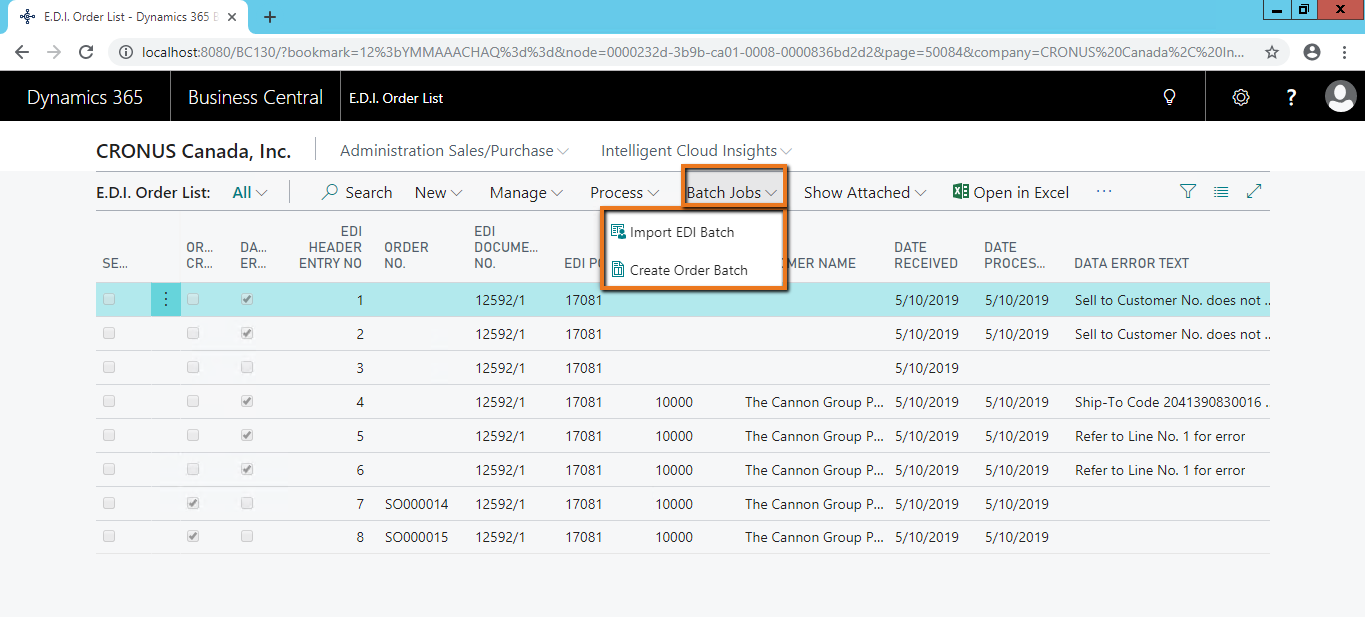

Companies are using automated invoice reconciliation to scale up their business processes, especially in centralized billing. If you own or operate several establishments, you will need to process invoices from multiple locations quickly and efficiently. EDI allows you to do this, even if your various locations are being run independently by different managers.

By using EDI and automating the manual collection of data, you can reduce processing errors and increase efficiency when reconciling invoices. Messy handwriting, wrong inputs, and scanning issues are no longer a problem. You can enter all the pertinent information into a terminal, generate an invoice electronically, and send a copy to a centralized office for automated reconciliation.

Automated EDI is one form of IT management that is transforming business infrastructure and processes. Automation reduces complexity and increases efficiencies that can affect whole work teams, replacing manual, error-prone processes, and saving many more useful employee hours spent on other tasks.

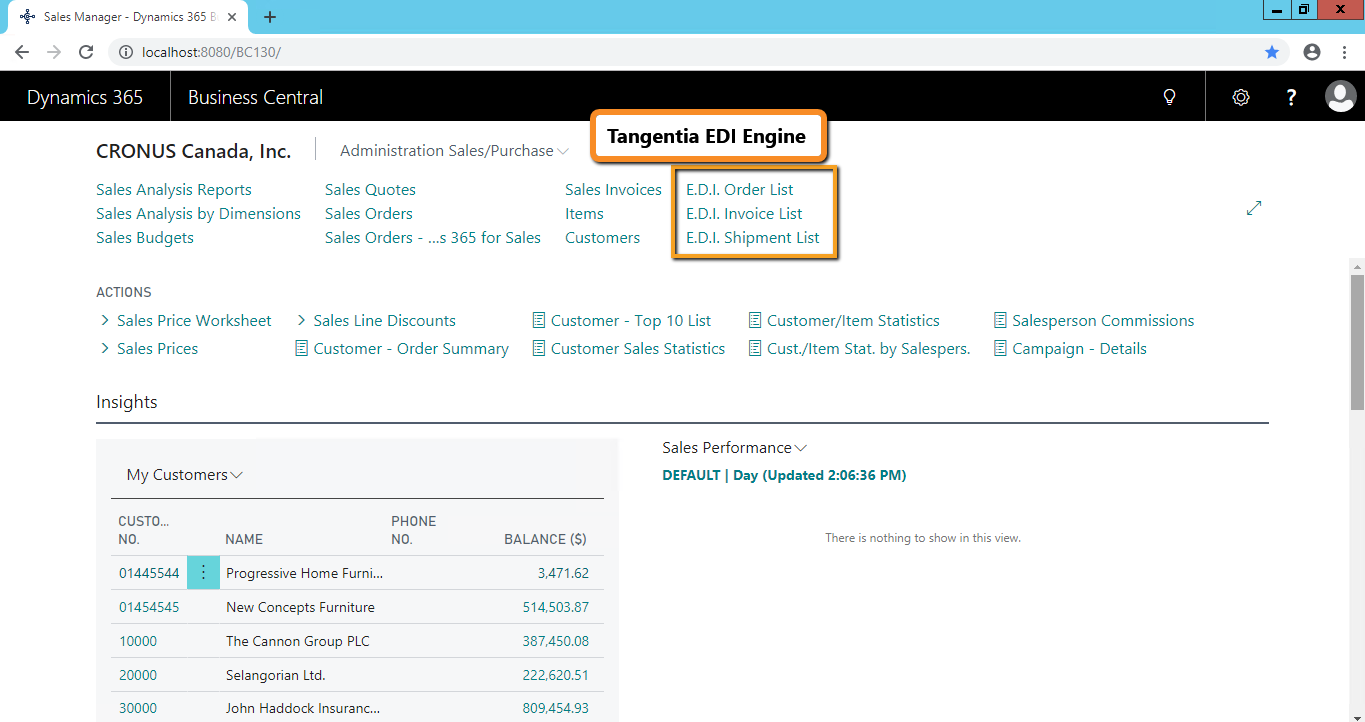

Seamless EDI and Business Automation Starts With Tangentia

How is your company leveraging powerful cloud EDI functionality and automation to transform your invoice reconciliation processes?

Tangentia provides digital solutions for businesses of all sizes. If you’re looking to kickstart your automation journey, we can help. Get in touch with one of our EDI specialists today to get started.

Get Started Today

Tangentia is a Platinum Partner of IBM and well as partners with Automation Anywhere, UI Path, Blue Prism, Adobe, Microsoft, Salesforce, Amazon and leading enterprise software vendors. We work with customers globally with offices in Canada and India to implement their RPA strategies using an agile methodology.

Read Now