The manufacturing sector is undergoing a transformative revolution with the advent of Generative AI (GenAI). This technology, which encompasses advanced machine learning models capable of generating new data and patterns, promises to redefine the industry’s landscape, driving unprecedented innovation and efficiency. At Tangentia, we are at the forefront of this transformation, helping businesses leverage GenAI to unlock new potentials and future-proof their operations.

The Role of GenAI in Manufacturing

GenAI is not just a technological upgrade; it represents a paradigm shift in how manufacturing processes are conceptualized, executed, and optimized. Here are key areas where GenAI is making a significant impact:

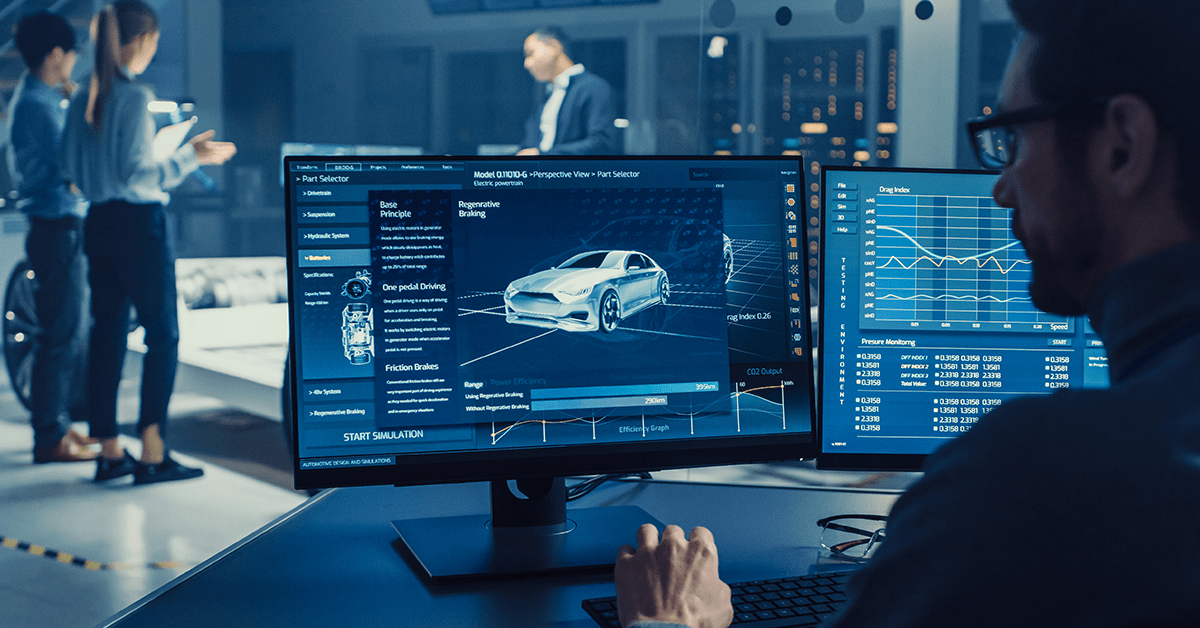

Design and Prototyping:

- Enhanced Creativity: GenAI algorithms can generate novel designs and prototypes based on vast datasets, enabling more creative and efficient product development cycles.

- Rapid Iteration: With AI-driven simulations, manufacturers can quickly iterate on designs, reducing the time and cost associated with traditional prototyping methods.

Predictive Maintenance:

- Minimized Downtime: By analyzing data from sensors, machinery and other IoT devices, GenAI can predict equipment failures before they occur, allowing for proactive maintenance and minimizing production downtime.

- Cost Efficiency: Predictive maintenance helps in reducing the overall maintenance costs by addressing issues before they escalate into significant problems.

Supply Chain Optimization:

- Enhanced Forecasting: GenAI can analyze market trends, demand patterns, and supply chain variables to provide more accurate demand forecasts.

- Efficient Logistics: AI-driven insights can optimize inventory levels and logistics, ensuring a smooth and cost-effective supply chain operation.

Quality Control:

- Automated Inspections: GenAI-powered vision systems can perform real-time quality inspections, identifying defects with higher accuracy than human inspectors.

- Consistent Standards: By continuously learning and adapting, these systems maintain high-quality standards across all production batches.

Get a free Proof Of Concept

Sign up for a free POC worth $5000 for Tangentia's TiA implementation at your manufacturing site. Book a discovery call with us today to find out more about what Tangentia Intelligent Automation solutions can do for you.

Tangentia’s Expertise in Implementing GenAI

At Tangentia, we understand that implementing GenAI in manufacturing requires more than just technical knowledge; it requires a strategic approach that aligns with your business goals. Here’s how we can help:

- Customized Solutions: We offer tailored GenAI solutions that fit the unique needs of your manufacturing processes, ensuring seamless integration and maximum impact.

- Scalable Implementation: Our team ensures that your GenAI deployment is scalable, allowing for future growth and adaptation as your business evolves.

- Comprehensive Support: From initial consultation to ongoing support, Tangentia provides end-to-end services to ensure your GenAI projects are successful and sustainable.

- Expert Training: We provide training for your workforce to effectively leverage GenAI tools, ensuring that your team is equipped to maximize the benefits of this technology.

The Future of Manufacturing with Tangentia and GenAI

The future of manufacturing is here, and it is powered by GenAI and Intelligent Automation. At Tangentia, we are committed to driving this autonomous transformation, helping businesses harness the power of AI to achieve new heights of innovation and efficiency. By partnering with us, you are not just adopting a new technology; you are embracing a future where your manufacturing processes are smarter, more agile, and more competitive.

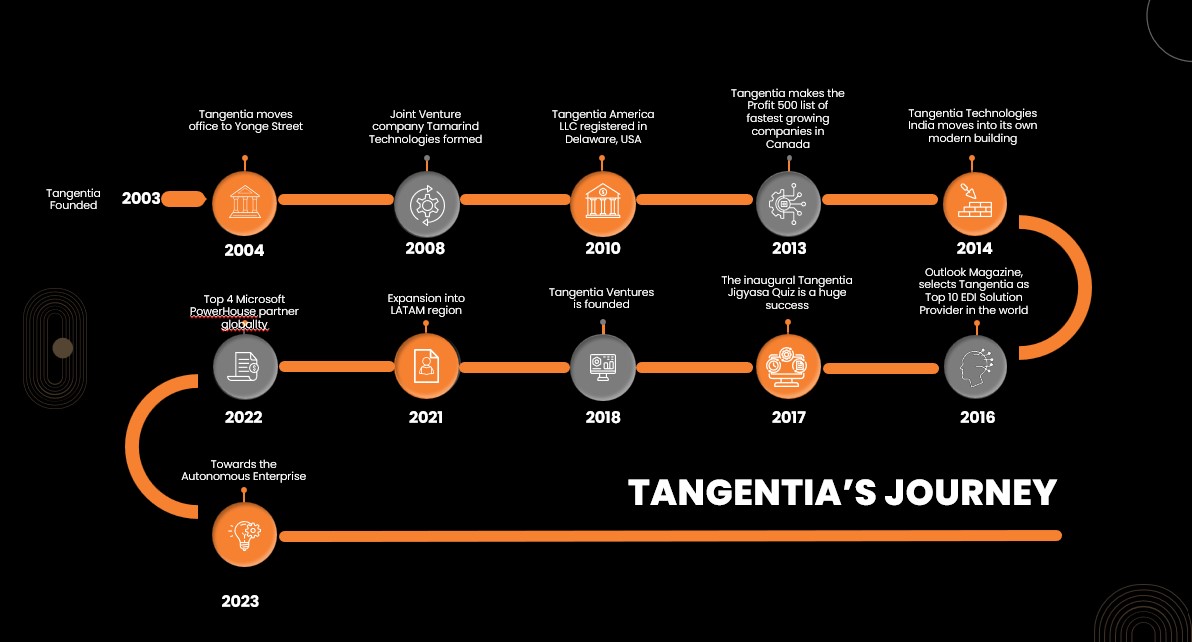

-1-1.png?upscale=true&width=1200&upscale=true&name=Copy%20of%20Tangentia%20Year%20end%20post%20(600%20x%20299%20px)-1-1.png)