We’re fast approaching the end of life for Automation Anywhere’s Enterprise V11 platform. That’s not a bad thing, however. The industry-leading RPA vendor is replacing the client-based, a legacy solution with something more agile and modern — Automation 360, formerly known as A2019.

You already know this, of course. That’s why you’re here. You don’t need us to convince you about the value of RPA — you need to convince the decision-makers in your business.

Fortunately, that won’t be difficult to do. As you’ll soon see, the numbers speak for themselves. First thing’s first, however, you’re going to need a plan.

What Is A2019/Automation 360?

The latest iteration of Automation Anywhere’s robotic process automation (RPA) solution, Automation 360 is completely web-based, rebuilt by the company from the ground up. It neither relies on specialized infrastructure nor requires an on-premises installation. This allows it to provide greater functionality, better scalability, and improved ease of use at a lower total cost of ownership than its legacy predecessor.

Automation Anywhere has made a few other changes with Automation 360 as well, including:

- Support for CENTOS and Red Hat Enterprise Linux.

- UI is available in 7 additional languages, bringing the total supported languages to 10.

- Available on-premise, as a SaaS app, or as a hybrid deployment.

- Web-based bot creator platform.

- Cognitive technology and artificial intelligence are available out of the box.

- Task commands have been replaced by modular, package-based “actions.”

- A new SDK allows customers to develop their own packages.

When Does Automation Anywhere V11 Reach EOL?

As of March 2021, Automation Anywhere stopped selling Enterprise V11. The product’s official end of life date is September 2022.

The Challenges of Migrating to A2019 from Enterprise V11

To leverage the advanced functionality of Automation 360 and support ongoing business continuity, you need to migrate to Automation 360 as soon as possible. Unfortunately, that’s easier said than done. Because the two versions are so fundamentally different from one another, there are multiple roadblocks to account for :

- Bot Migration. Bots migrated from V11 to A2019 do not preserve system credentials, meaning these must all be reconfigured manually after migration. Additionally, some bots do not even support migration.

- Code Differences. Automation 360 has completely retooled how task commands are handled — among other changes — there’s a lack of code parity between the two versions.

- Versioning Issues. It’s difficult to access historical versioning data on bots and other components after they’ve been migrated, which is a significant issue from a compliance standpoint.

- Audit Log Storage. Automation 360 changes how audit logs are stored, which can potentially mean retooling your auditing and reporting processes.

- Output. Automation Anywhere does not offer any straightforward means of comparing outputs for migrated bots, meaning you’re flying blind when it comes to testing whether or not your bots were successfully migrated.

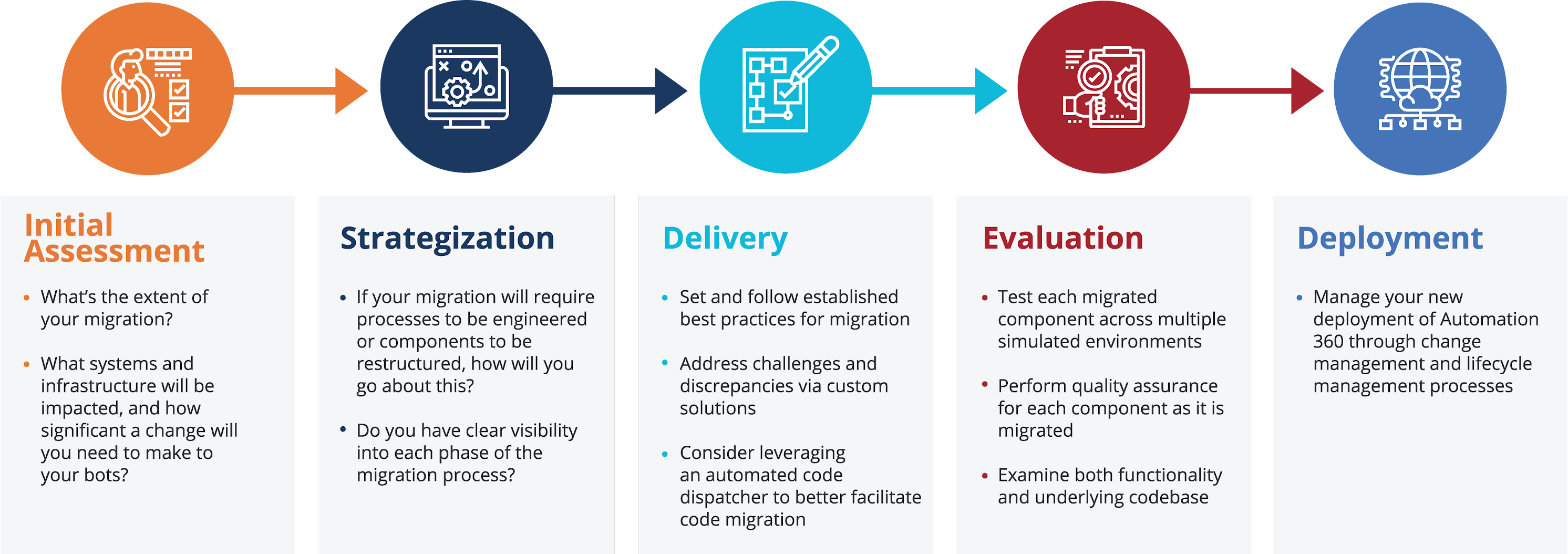

Planning Your Migration Strategy

Successfully migrating to Automation 360 begins with laying the proper groundwork. You’ll need to take a measured, deliberate approach, assessing and evaluating your progress and infrastructure at each phase. Here’s how that looks in practice:

Initial Assessment

- What’s the extent of your migration?

- What systems and infrastructure will be impacted, and how significant a change will you need to make to your bots? You’ll want to pay especially close mind to version differences.

- Do you have measures in place to address any potential business continuity challenges that come up?

- What is your threshold for solution complexity?

- Are there other improvements/optimizations that can be made during the migration? New features of Automation 360 that you could incorporate?

Strategization

- If your migration will require processes to be engineered or components to be restructured, how will you go about this?

- Do you have clear visibility into each phase of the migration process?

- How will your migration be timed? Have you set realistic targets?

- What business needs do each individual component serve, and which take precedence in terms of migration?

Delivery

- Set and follow established best practices for migration, such as those provided by Tangentia.

- Address challenges and discrepancies via custom solutions.

- Consider leveraging an automated code dispatcher to better facilitate code migration.

- Reuse code where possible, and cut out redundancies where you can.

Evaluation

- Test each migrated component across multiple simulated environments.

- Perform quality assurance for each component as it is migrated.

- Examine both functionality and underlying codebase.

Deployment

- Manage your new deployment of Automation 360 through change management and lifecycle management processes.

Ensure a Seamless Automation 360 Migration with Tangentia

The prospect of such a complex migration can be both daunting and discouraging. If you’re like most businesses, you likely cannot afford the extensive downtime that would be required. Especially now, you need your RPA platform performing at peak efficiency, with as few interruptions as possible.

As a Gold Automation Anywhere Partner and a global leader in RPA, we employ more than 50 trained and certified developers, business analysts, architects, and project managers. Together, these experts have developed a migration process that gets you up and running on Automation 360 as quickly and painlessly as possible. Working with our highly experienced team, you’ll also be able to leverage our powerful, cloud-based Automation Anywhere Platform.

Working with Tangentia, you’ll be able to effortlessly move past any challenges that might prevent a successful migration:

- Build Better Bots. With our Bot Factory, get the bots you need the moment you need them.

- Our dedicated team designs develop and test your bots, including tackling all the challenges associated with migrating.

- We maintain a Bot Operations Center to provide full support post-migration.

- We’re able to easily spin up virtual testing environments for the purpose of output comparisons.

- Maintain Code Parity. Between our expertise and our extensive code library, we’ll help you sort through any unsupported components as you move from one platform to the other.

- Preserve Version History. We’ll make sure that even post-migration, you don’t lose versioning data. We’ll keep it securely stored and readily accessible for all your compliance needs.

- Keep Your Audits Intact. Whatever your auditing and reporting requirements, we’ll make sure you meet them, no matter how complex your migration is.

Before you migrate to Automation 360, it is important to verify the migration readiness of your bots. You can scan your bots using Automation Anywheres Bot Scanner and analyze the generated report for information about their current state.